I was reading a forum post on Slowtwitch that a Facebook friend described as the greatest post ever (sorry I can’t remember who linked it), and thinking that it read a lot like something Josh Poertner of Zipp would write, but it was by a certain ‘joshatsilca’. A couple of clicks later it’s revealed that Josh Poertner had left Zipp and bought Silca, and was sharing a lot of the knowledge he gained over the years. Among the nuggets are a post on lightweight wheels and Andy Schleck, a post about Lance Armstrong in the wind tunnel, and one about how Alberto Contador refused to accept scientific data.

I called Josh up for a quick chat and then we conducted the following interview via email. (photo courtesy Joe Vondersaar)

AS: How does an engineer at a tech driven company like Zipp go to an old world craftsmanship company? How’s all the knowledge you’ve gained going to change bike pumps?

AS: How does an engineer at a tech driven company like Zipp go to an old world craftsmanship company? How’s all the knowledge you’ve gained going to change bike pumps?

JP: It so easy to look at inflation and think that the whole category is completely understood, sorted out and saturated with products…in a sense, it’s over and done. That was my first thought when Claudio Sacchi (grandson of Silca founder) called me about buying the company. However, after thinking about it and researching a little bit, I realized that there is so much that is technically unknown, unsorted, and not yet done in cycling regarding tires and pressures. Generally the people who are most excited and full of ideas when they hear about SILCA are my friends in auto racing.

Racecar engineers are always quick to point out that you might have a few dozen people in an F1 or LeMans pit, and generally at least 2 of them do nothing but take care of tires and pressures, not to mention the equipment that race teams have dedicated to tires and pressures. The tire is the ONLY thing connecting you to the road, every single other thing happening in a race car is happening on the other side of the tire. Same thing with a bicycle, every single aspect of handling has to be transmitted through the tire to reach the road. Without it, nothing happens, and yet, we hardly pay any attention to it. In fact we continue to prioritize other areas where the performance advantages feel large, but are often minimal.

Now, with SILCA, the excitement for me personally is in the collision of history and craftsmanship with technology. I’ve long shocked people with my affinity for handmade steel bikes, old Campy components and general feelings about things like bike computers (won’t use one). I love to ride and to go fast, but at best I get to ride one or two days a week so my power is quite limited, and my time even more so. What I like is perfection. I want my bike to be clean and silent, to feel beautiful under me and to look great. My two criteria for buying a bike are values of the company/person building it, and the paint job. People often forget about the people behind companies, but in reality, that’s really important, and for me it further enhances my love of riding and bicycles in general.

Some of my closest friends in the industry are on the handmade side of the business, which makes sense when you consider that only about 10% of what we did at Zipp is what people would think of as ‘high-tech’. At the end of the day, what you spend most of your time on is executing the ideas that you have. For many companies executing ideas is something that happens at the supplier…but at a company like Zipp, you spend your time developing tooling, work holding, manufacturing prototypes by hand, doing your own testing, etc. Much of it is very low-tech and very hands on, and I wouldn’t want it any other way, for me that’s the fun stuff!

In that regard, SILCA really isn’t much of a departure from a day to day perspective. Technically I’m doing many of the same things as I did before, but I’m enjoying the ability to really put the focus on beauty over weight!

So to get back to your question, I was very excited by the prospect of bringing our industry to a new level in the inflation category, and even more excited to be able to do it with a brand and product deeply tied to craftsmanship and beauty.

AS: One of the recurring themes I get from your Slowtwitch postings is the inaccuracy of riders’ subjective sensations. Yet those sensations drive so many equipment choices, at both the pro and amateur levels. Can you talk a little about our subjective interpretation of speed and comfort, and why it’s often skewed?

JP: So one of the things I’ve learned over the years is that we are frequently more sensitive to a persuasive argument or to confirmation bias, than we are to the small variations across similar products. In a sense, we all think we are better at ‘feeling’ differences than we are. Most interestingly, things that have large affects on performance like aero or tire rolling resistance aren’t generally perceived very well at all, yet can yield large differences.

I use an analogy of a Jeep Wrangler vs Mercedes S Class on the highway. You could be a passenger in the S-Class at 80mph, comfortably reading a book and hardly aware of the speed you are traveling, yet at 80mph in the Wrangler, even with doors on and the roof up you may very likely be fearing for your life, especially if the road surface is less than ideal. The technical reality is that in both instances you are traveling 80mph…the speed is the same, but the perception of it is VERY different.

Similarly I meet people all the time who swear how fast a certain tire feels vs another, which may be costing them 6-10 watts per tire! While at the same time talking about how they upgraded to ceramic wheel bearings and can feel the improvement, which is likely 0.5-1.0 watt total. We see this with tire pressures in testing all the time, high pressures feel faster, yet are most always slower, but we are perceiving speed through other things like high frequency vibrations, so we feel faster with higher pressure.

At the end of the day, I can only say we’ve found 2 factors in human response data that correlated with things that were measurable (in terms of speed/performance/comfort). One was aero differences, though usually riders just noticed this when they were instructed to try and ride with similar power values and they notice higher speeds as they are riding laps over the same course.

Rarely do riders come back saying, ‘wow, I was faster’ but the engineers could blindly look at a pile of data and instantly pick out the aero equipment. Aero really does matter whether the rider ‘feels’ it or not.

The second one is tire pressure, which is almost always assumed to be a more comfortable frame or wheels, or whatever the product focus is on for the test. It is amazing to think about how quickly we are to ‘feel’ a difference between this handlebar and that, or this frame and that, different wheels, etc. before we ever even think about tire pressures.

I was shocked in the early days of our attempt to be the first carbon wheel to finish Roubaix to find that the difference between a longer wheelbase cobble specific race bike with curvy seat stays and numerous ‘comfort features’ and its standard race bike cousin which everybody ‘knows’ is too stiff for riding the cobbles, equates to an air pressure difference of less than 10psi, and generally depending on which bikes you are comparing, the difference might only be 3-4psi equivalent pressure difference between the two.

Of course, all of these things are all cumulative, the more compliant bike is useful because we use it in addition to the tire pressure, wheel and tire choice and other factors to tune the total system performance, but at the same time nobody ever gets on their bike with yesterday’s air in the tires and thinks, ‘Wow, I must be down 4 psi from yesterday because the difference in comfort is amazing!’

AS: Can you explain the concept of stacking springs in series, and how that relates to tires, wheels, and frames?

JP: Springs in series add using the principle of 1/keq=1/k1+1/k2 where k is spring rate, so 1/k equivalent rate = the sum of 1/individual rates.

This makes sense if you think of a really stiff spring sitting on a really soft spring, if you load them both, they both see the load, but the soft one does most of the deflecting. For our purposes, the tire is spring1, on which sits the wheel: spring2, attached to the frame: spring3 and seat post, spring 4. For simplification purposes, we generally try to just take a base measurement of the larger things to simplify…so rather than looking at a frame as sum of its spring parts, we might fixture it at the rear dropouts and push on the seat rails…or something like that. A wheel is usually looked at by pushing a flat surface against the rim edge while the hub is rigidly fixtures. We look at tires similarly and then either use a solid steel test wheel, or measure the tire on wheel and then reverse the math to get the tire portion since we already know the wheel.

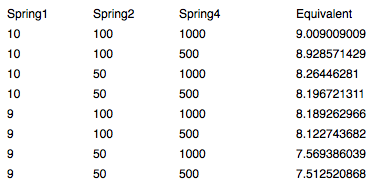

So if we take springs with rates of 10n/mm, 100n/mm, and 1000n/mm and we put them in series, they add up to an equivalent spring rate of 9.009001n/mm. If we tweak the rates we can make a little chart like this one:

So the point I’m trying to get people to think about (and it is something that has completely changed the way the top 3 or 4 pro teams approach classics equipment) is that we love to obsess over the 100 and 1000n/mm springs, while generally completely neglecting the 10n/mm spring.

In time I’ll present data with real component values to further illustrate these effects in real world terms. In a nutshell, everything makes a difference and clearly there are differences if you take 2 frames with 4psi equivalent pressure difference between them, and then run the softer one with 4psi less pressure, you will without doubt have a more compliant system.

AS: To dumb it down, using the first two numbers in your chart, is it fair to say you can have a frame be twice as compliant alone in a test jig, but when you actually build it into a bike and ride it, the system will only be 1% more compliant?

JP: Essentially yes, but more like 2-3% when using real world frame stiffnesses.

AS: If the effects of frame compliance are minimal to imaginary, should we just pick frames for aerodynamics? And what’s the correlation between the much touted ‘lateral stiffness’ and efficiency?

JP: I’ve never seen any data or study on frame lateral stiffness affecting performance. It has often been theorized that power losses due to frame flex are very small due to the efficiency of energy return in the system, but I’ve never studied it specifically or seen anybody that has.

What I will say is that we’ve done ride studies with power/speed data including quite a bit using the Alphamantis Aerostick and when looking through the rider data, you can never see stiffness effects show in a real way. This is different than feeling a difference when you ride it, I’ve ridden a TVT carbon bike from the early 90’s and you can feel AND even see the thing flex, but amazingly, if you are looking at speed/power data, you cannot conclusively find differences. Which doesn’t mean they aren’t there, it just means that they are likely buried within the margins of uncertainty of the equipment used in the testing.

Lateral wheel flex is something we’ve looked at extensively and the theoretical linkage is something like 0.5watts lost to wheel flex under heavy acceleration. So call this 500 watts of input and you then realize that even with a +/-1% laboratory grade power meter, 0.5% error in speed measurement, 0.5% error in wind speed measurement, 1% uncertainty in wind angle, you see that it is just impossible to actually find that 0.5 watt in the data.

This is where aero has such an effect, I can sit in front of ride test data and instantly pick out the aero bikes/wheels. The telltale giveaways are that the ascending data compresses to match the non-aero, the flat land data shows consistent speed improvements with similar power, and the downhill sections show significant gains that increase with velocity. In similar testing, you can take a kilogram out of the bike, and just not see it. You can make 2 identical wheels with a 50% stiffness difference (done it) and not see it in the data.

AS: Let’s talk a little about tires. It seems that conventional wisdom is moving towards larger tires and lower pressures. What speed secrets can you share with us?

JP: The trend is toward wider tires and lower pressures and this really is a good thing for everybody. The only downsides to wider tires are increased weight compared to narrow tires of similar construction and decreased aero performance due to the extra width.

As we’ve talked, the weight is much more an issue we obsess over than it is an actual performance issue. As for aero, it can make a really big difference, but the top wheel manufacturers are now developing for this and it’s making a big difference. At Zipp we were developing new wheels around 23’s and testing with 25’s to ensure consistent performance.

At issue with aero is that aero effects are non-linear, so on an older style wheel you might have a 3% increase in drag from a 21mm to a 22mm tire, but a 25% increase in drag with a 23mm tire and a 60% increase with a 25mm. This was key to the original super wide 303, at 28.5mm wide, the wheel has only about a 7 or 8 gram increase in drag with each mm of additional tire width between 21 and 27mm, which means that when comparing with 27mm tires, the 303 had half the drag of similar wheels of older design.

Another factor never spoken of is how tires deform and grow with pressure. We learned this early in the Phonak days when they had mechanics obsessed with incredibly high pressures. This is a good example of how the conventional wisdom of a few can affect an entire team. They were running 180+psi in their TT setups, regardless of road surface and tire.

We went to the wind tunnel and were working on 21 vs 23mm tires and found that the 23mm tires were terrible compared to our historical data. Upon measuring, the 23 at 180 measures more like 25.5mm wide, but more importantly, as the tire grows, it becomes more round, which is significantly less aero. So the 23mm tire at 100psi was significantly faster than the 23mm at 180psi with lower drag and significantly higher stall angle both wheel only and in bike.

Every tire is different, but again these effects are non-linear, they gradually get worse and then the data sort of explodes (in a bad way). Hard to generalize completely, but from an aero perspective, you are almost certainly better off with a 25mm tire at 100psi that measures 25mm wide, and you are with a 23mm tire at 150psi that measures 25mm wide.

AS: You mentioned latex tubes as well. What magnitude of savings do you get with them? Are they the best examples of a cheap and unsexy upgrade that produces big gains?

JP: Yes, latex is probably the best bang for the buck upgrade you can ever make to any of your bikes. They are definitely more labor intensive to install than butyl, and you have to pump them up every day…but you can save 3-5 watts per wheel(!) compared to butyl. At the moment, tubeless is getting better, but still nobody has a tubeless system as efficient as a high quality standard tire with latex inner tube.

Putting it in perspective, that $20 latex tube at minimum would be worth maybe 3 watts in a front wheel compared to $1000 for the best ceramic bearings which might get you 0.8-1 watt for a wheelset upgrade.

AS: Finally, what can we look forward to from you and Silca?

JP: Without giving too much away, my goal is to bring exceptionally well made products to market, filled with the sort of passion and craftsmanship Silca has been known for over the past 96 years, while adding elements of technology and research from my background. Cyclists will be able to look to us for both products as well as data, information, and best practices. I think we will be able to surprise people as we blow up some of the conventional wisdom out there, and in other cases, we can affirm the conventional wisdom and then give people the tools to follow through and really enhance their own experiences.

At this point I thought we were done but then I couldn’t resist one last question.

AS: If I made a frame with the finest carbon and laid it up in the smartest way possible, then made another frame with cheap carbon haphazardly placed in the same mold, would anyone be able to distinguish them in a blind test? If the test subjects were told the lousier bike was the better bike, would they convince themselves of this? (Assuming the badly made one doesn’t fall apart immediately.)

JP: There are a couple of angles to your question, which is a really, really good one!

First, the whole thing about different grades of carbon and everything around that. At the material level, this is a big deal, but not always how it is presented in marketing and sales literature. Carbon comes in all sorts of different fiber types which have varying levels of stiffness (modulus). Our industry talks a lot about ‘High Modulus’ but truthfully bicycles really can’t be made from true ‘High-Mod’ or at least not with more than a little bit of it, as true, high-modulus carbon can be exceptionally brittle. You might be able to use a patch of true ‘High-Mod’ somewhere in a frame or a part, but in all honesty, if you made a bike frame from the high-mod materials used in satellite solar panels, you could likely shatter the thing in most any incident.

In general, things like $1000 per pound carbon used in satellites, is chosen for having near zero or slightly negative thermal expansion along with exceptional stiffness, really to the point of being quite brittle, great in space, not so much in a bike race. What I believe is generally done, is that in inner ply or patches of 58-60Msi (the lowest of the high-mods) is used and then more damage tolerant materials encapsulate that, but from firsthand experience, most companies are using predominately standard or medium modulus materials.

Over the years we had made rims from hundreds of materials and honestly it is hard to see much difference between the middle 80% of them as the slightest variation in layup, resin flow, pressure, most anything will make your T800 rim look just like a T700 rim. Many of the low cost commercial grade Asian materials that really are lower strength, lower stiffness and lower elongation, so there are materials out there where you would be hard pressed to make a good part with them at any reasonable weight, but there are companies out there using the stuff so beware.

The real secret sauce in carbon production is the resin, which is the thing nobody ever wants to talk about because it risks revealing too much, and honestly it’s quite boring. But amongst experts, the resin is really the most important part of the whole equation, and from tests I’ve been a part of, you are better with a slightly lower grade fiber (within limits) and higher grade resin than the other way around.

When we developed Firecrest carbon clinchers we ended up using a very exotic resin system that not only had exceptional thermal behavior, but was stronger, stiffer and more damage resistant than anything we’d seen before it. Sadly, the resin was considerably more expensive per pound than the high grade carbon we were using, but the difference was amazing, we could make 2 rims with identical fiber type and content and the superior resin made one of them stronger, stiffer, more heat and damage resistant..though at a high cost. Remember, the properties are hybridized, you are ideally only 55-60% fiber, so 40-45% of your ‘carbon’ part is resin.

At the end of the day, there are so many ways to make poor carbon parts that it’s amazing anybody can make excellent ones. So you have only a few degrees of error when you are initially laying out and cutting the material (at Zipp we had laser layout and CNC cutting which yields +/-0.5 degree, but +/-3 degrees can be common in table layups and at 3 degrees off axis you have lost the difference between T800 and T700 in properties!), then you can’t contaminate it with things like skin oils, airborne particulates, etc. Somebody using mold release or any number of other chemicals in the same building can cost you a few percent in strength…it’s that sensitive, so you have to have at the least separate HVAC systems or at best a clean room.

Then you have to lay it up wit the utmost precision, maintaining all your angles and orientations, while making the fabric drape exactly to form without wrinkling or trapping air between plies, and again without contaminating. You have to mold it, and that is so sensitive to temperature and pressure, how and when the pressure comes on, etc…literally there are volumes of hardbound books on just that topic as things like resin outgassing, microscopic trapped air bubbles, wrinkles, etc will all cost you.

Then de-mold, clean, remove the flash, drill or machine without overheating resin or tearing fibers, etc. So all said and done, differences at the fiber level will only appear when everything else is exactly perfect…and even then you can only expect a few percent gain due to the material as even a 30% stiffer material is only affecting 55-60% of the matrix, and then only on the plies in the direction in which you are measuring, so for example if you have 2 plies out of 10 that run axially down a tube and you are testing tensile stiffness of the tube, your high mod material is adding 30% stiffness to 20% of the 60%…(I’m grossly simplifying here, but that’s pretty much how engineers would step through it in conversation).

Now people listen to me say this and then always ask about knock-off frames or cheap China direct frames, as they take what I’m saying to mean ‘raw material is not such a big deal.’ What I’m really trying to say is that all of it is such a big deal that you have to be hyper-vigilant about all of it. It’s really that raw material is only a big deal when everything else is perfect, so I’d recommend first on finding the company that is investing in being perfect, which takes a lot of resources and investment in very non-sexy things like cleanliness, tracking systems, air-filtration, employee training and workforce stability (do you want the new guy laying up your bike on his first day?) process controls, inspection, etc… It’s crazy to think, but good carbon costs about 10x as much as good aluminum, and good resin will cost almost as much or more than carbon…and by the time you are done, the cost of the materials is really just a fraction of the total cost of doing all of the individual activities correctly to make a perfect part.

Thanks Andy and JP. Great stuff!

I’ve also had bad luck with latex tubes. I bought a pair, which were great for four or five days. After a week they were losing 20-30 psi after 30 minutes on the road. Has anyone had better results and longevity?

also, I’ve noticed that after some time regular tubes stick to the inside of the tire…supposedly the increase in rolling resistance comes from the tube moving around in the tire as it deforms, but if the tube becomes attached to the tire (this is the way tubulars are made anyway) shouldn’t that mean lower rolling resistance and better handling?

I prefer sheepskin over latex for a more natural feel.

how do they taste?

careful, they leak

same fraud different product. 1 week left to buy better performance!

Haven’t ever had problems with Vittoria latex tubes and they have removable cores. Latex is inherently more porous than butyl and will require daily reinflation. The green Michelin latex tubes were good, but I think they have been discontinued.

Fascinating. Thank you!

at the end of the day?

Great stuff, thanks!

Really interesting article. Good stuff. However, I “feel” that JP under appreciates the power of confirmation bias to trump measurable, albeit minuscule performance improvement.

“good carbon costs about 10x as much as good aluminum”

All I need to know. Thanks.

Great article. He want to change his username since it sounds like he pooped a pump.

Awesome interview, would love to see more from him and stuff like this on NYV. Thanks!

You should try to get more information from him next year when he has had time to develop some cool stuff for Silca.

Does anyone know if there is any significant difference in reliability between latex and butyl tubes? One would think that 99.9% of the job of resisting flats is on the tire, not the tube.

They tend to be more flat prone… and sometimes split from regular inflation pressures

I had very bad luck with Challenge latex tubes. They were failing almost immediately. May have been a bad batch though. I went through 4 or 5 and finally decided it was too expensive.

Why is he coming back to Chinise manufactures twice in this article with slightly negative tone? Is Giant\Cervelo\Trek\Pinarello\and all others made on the moon or America? They are all Chinese and Taiwanese OEM carbon companies, they are not even Cervelo/Giant/Specialized companies they are OEM it means they might also produce carbon golf clubs at the back. They are the ones selling their molds for significantly cheaper, they are all made in the same carbon factories. Zipp is no other.

Want something American handmade including tubing choose crumptoncycles.com

Latex tubes are as reliable as any other, perhaps more so, with the STRONG caveat that installation must be perfect. They are much much more prone to peeking out past the bead of your tire. For whatever reason they tend to stick and not get all the way inside the casing. You absolutely *must* double check the entire perimeter, both sides, after getting the tire on, to be sure the tube is in there properly. Secondly, your rim tape must be perfect. A small spoke hole edge exposed might not kill a regular tube for months but latex will explode right through it immediately. Suggest two layers of stans no tubes tape, proper width, for best results.

So, if you got time for that, latex is good stuff.

In times that we have been interested towards these things it would just be a great thing to know any of those. – Flemings Ultimate Garage